Crimping Cable End Sleeves Ensure Reliable Connections

Cable end sleeves may be small, but they play a vital role in electrical installations. From distribution boards to machine wiring, they prevent wire strands from fraying and help maintain the mechanical strength of connections. Using the correct crimping method ensures a tight, reliable fit without air pockets, sharp edges, or risk of wire damage.

Klauke offers a professional range of tested and certified cable end sleeves, crimping dies and tools suitable for both industrial production and individual electrical installations.

Finely stranded copper wires are vulnerable to strand separation when connected to screw terminals without a cable end sleeve. A properly crimped sleeve secures the strands, improving contact and increasing the durability of the connection.

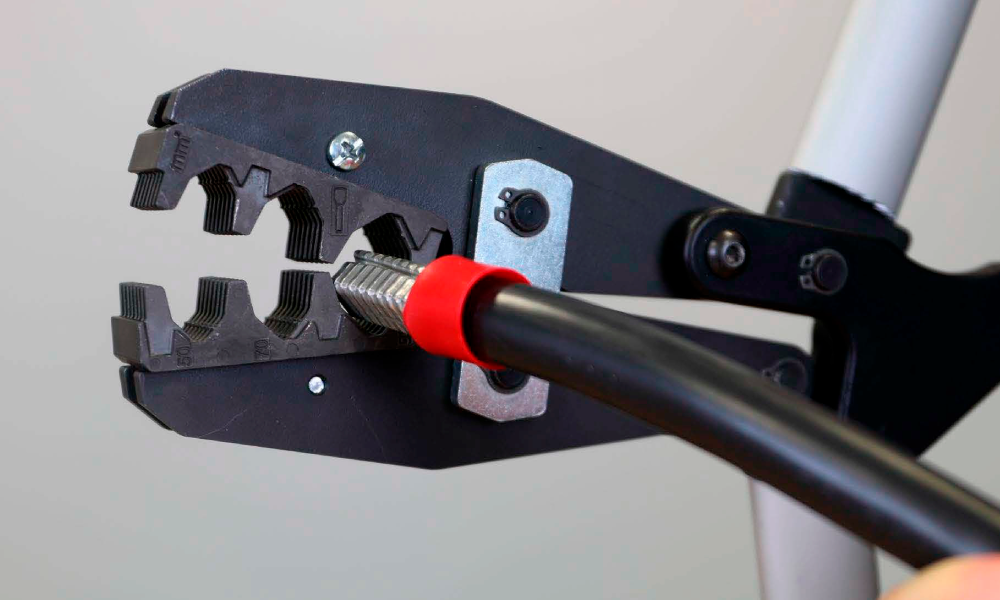

Proper installation begins with accurate wire preparation. The cable should be stripped slightly longer than the sleeve length. Klauke’s micro-strip tool allows for the strip length to be precisely and consistently pre-set by users. The correctly sized sleeve is then positioned and crimped using a compatible, tested tool. A precise crimp is essential for a safe and durable connection.

Crimping Technology and Tooling

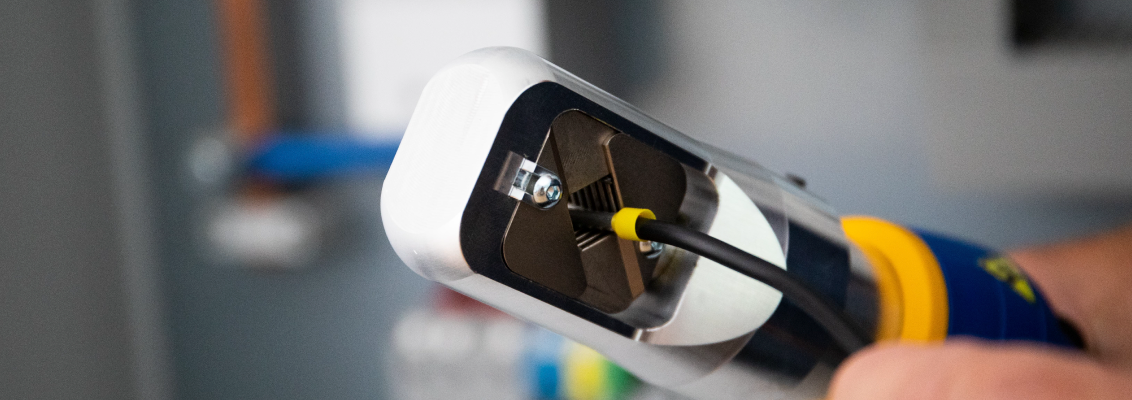

Traditional trapezoidal crimp profiles may leave air pockets and create sharp edges that compromise the wire. Klauke’s latest tools apply a square crimp profile with a comb-shaped design. This compresses the sleeve evenly from all sides, creating a symmetrical, compact, and clean connection. The square crimp is also highly versatile and suitable for most common terminal types, which helps make installations faster and more consistent.

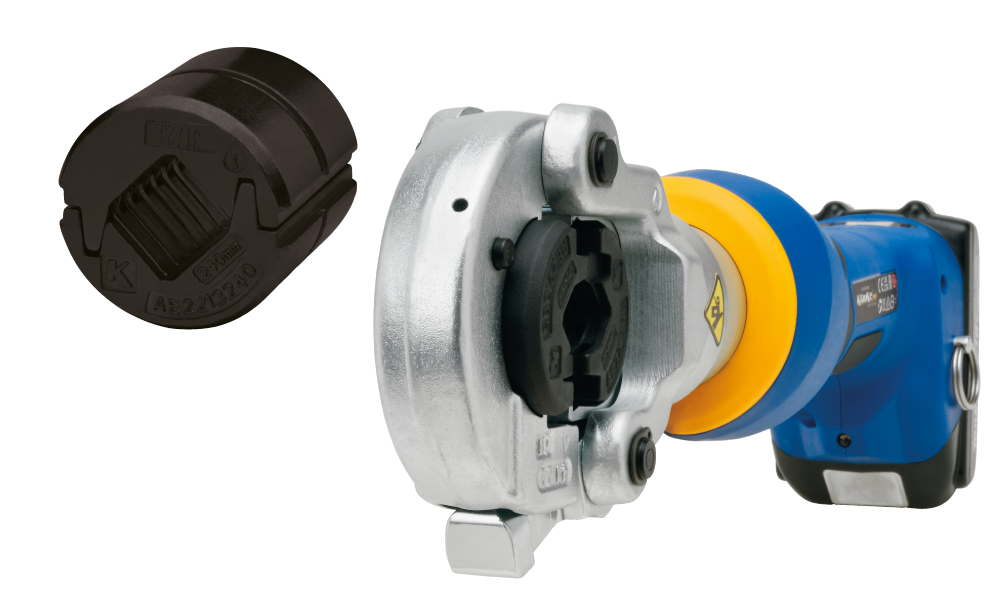

Klauke’s range includes tools for nearly all wire cross-sections. For smaller sizes, manual crimping tools such as the K507WF (0.5–50 mm²) and the K05WF series (25–95 mm²) offer a pre-clamp lever for easier handling in tight spaces. For greater force and repeatability, battery-powered tools such as the EK50ML (0.5–50 mm²), EKWF120ML (6–120 mm²), and the K13/K22 series (up to 240 mm²) offer both efficiency and ergonomic operation in field and workshop environments.

The AE2213 crimping die is compatible with multiple tool series and covers a wide range of cross-sections. One die fits several tools, reducing tool changes and simplifying on-site tool management.

Cable end sleeves are specifically designed for finely stranded wires (Class 5 and 6, DIN 46228), which are commonly used in machine and control panel wiring. In Class 2 wires, sleeves are generally not necessary, as strand separation is less likely. However, using sleeves makes it easier to insert the wire into the terminal and helps prevent installation errors. They also make rewiring or adjustments cleaner and safer, especially when working with push-in terminals.

A carefully crimped cable end sleeve provides a mechanically secure and long-lasting connection—exactly what is needed in any professional electrical installation. Klauke’s tools not only meet industry standards but also make it easier to perform high-quality installation work efficiently.

If you need help selecting the right tool or want to learn more about crimping cable end sleeves, feel free to contact us. We’re here to help you find the best solution.